Help Diagnosing Failed print cause

Posted: Tue Aug 06, 2019 6:23 am

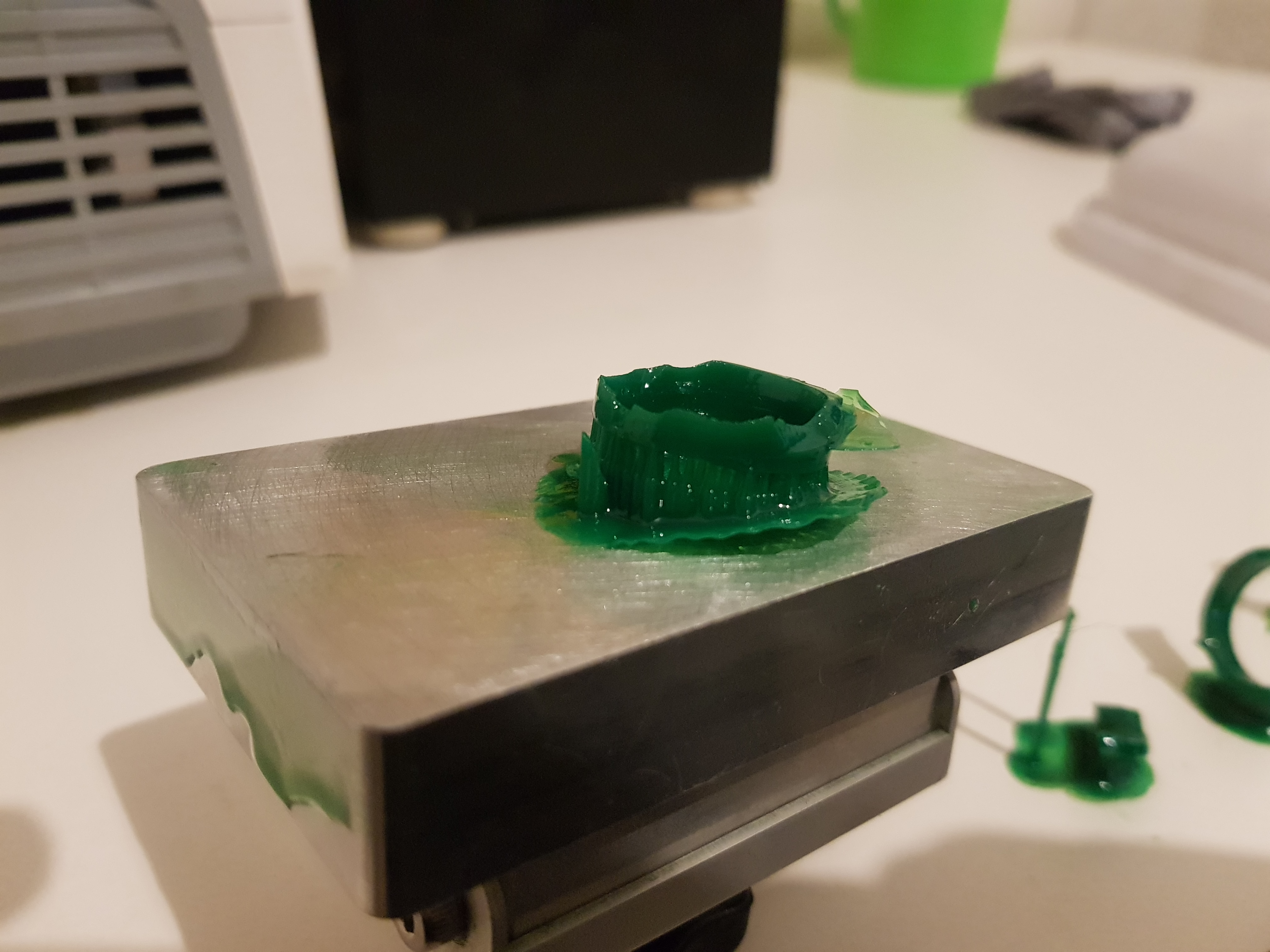

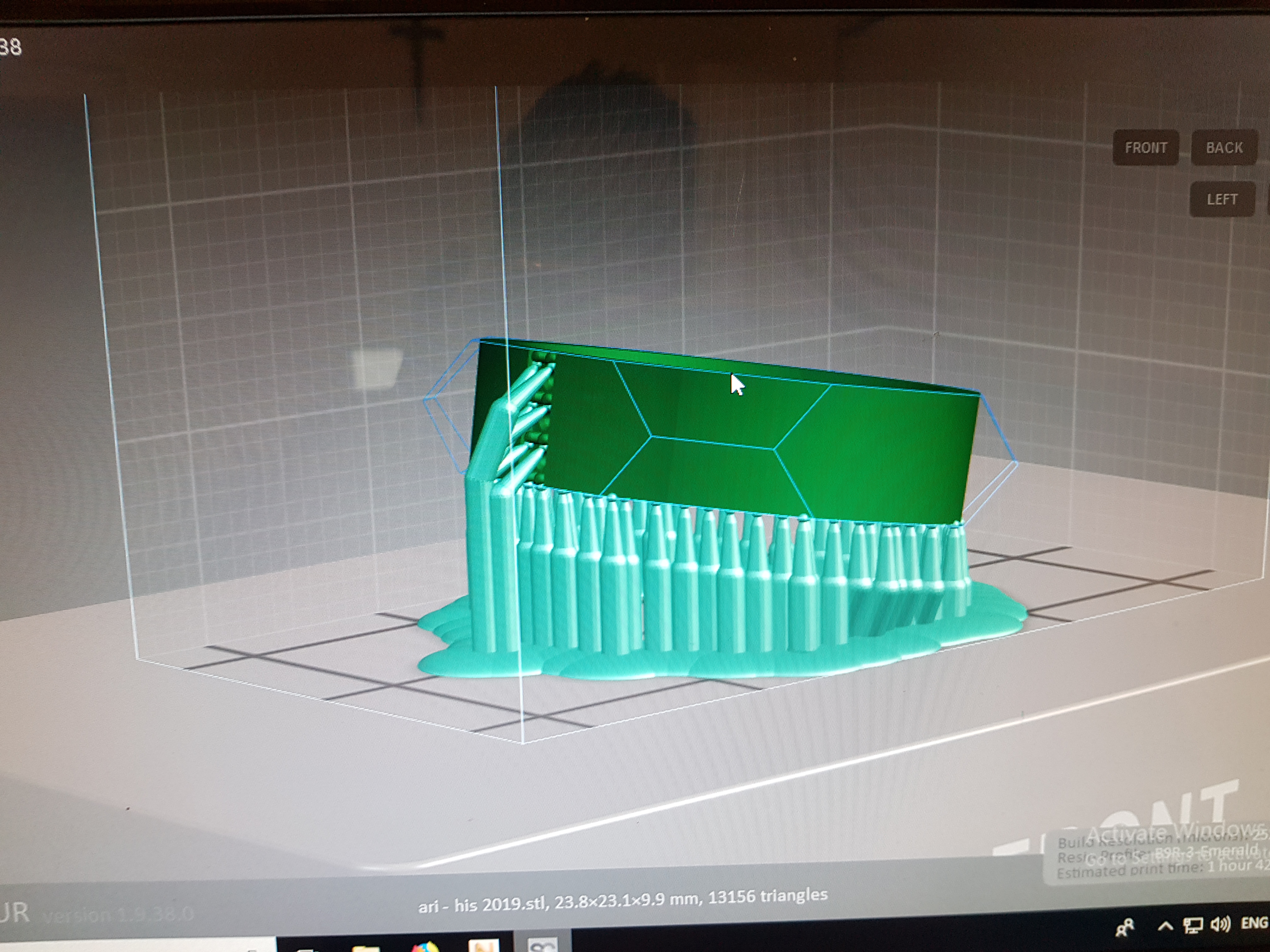

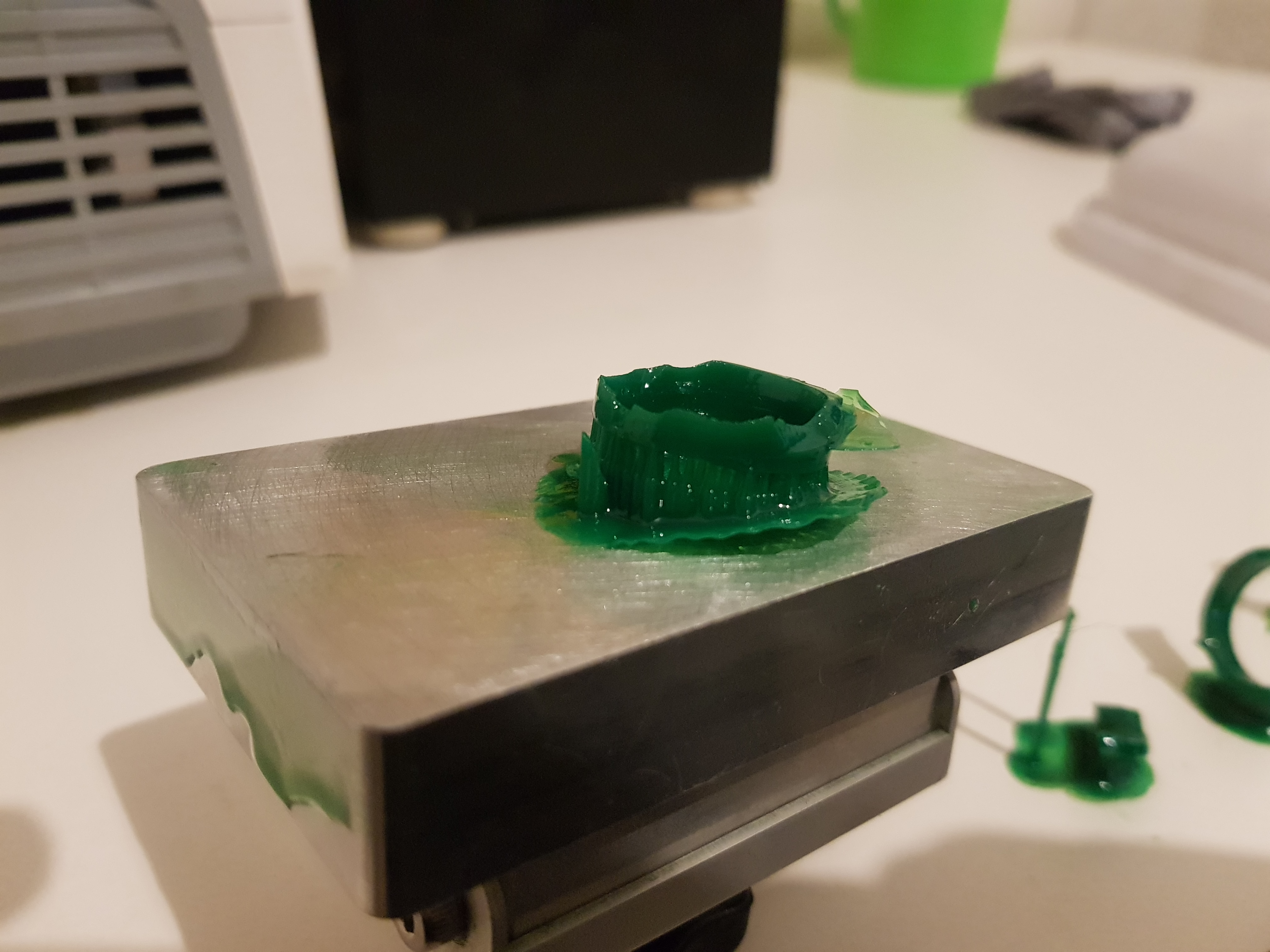

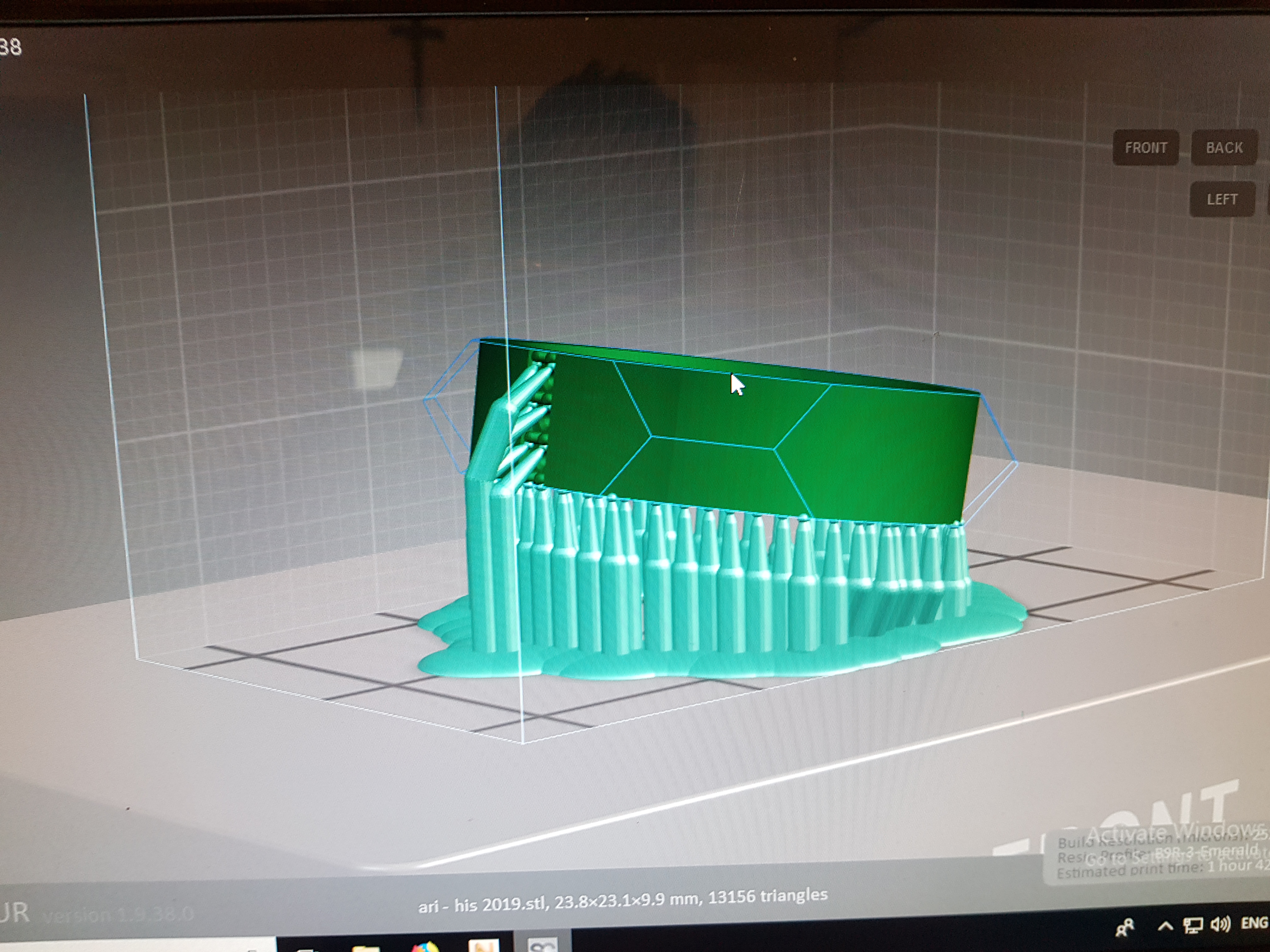

Hi Everyone, can anyone help me figure out why I am getting these fails all of a sudden?

Out of curiosity does most of everyone print on 80x45 rather than 48x27?

I was printing really well on 80x45 by finding a system of correcting the exposure settings by a method of: If the item is unformed - raise the exposure... if it gets flashing - reduce it. This served me well and I was printing at about 90% success.

There is a 'brighter' side of the table which you can notice when projecting white after a print, which was the more successful side of the table, so I thought I would change to 48x27 to reduce this.

After changing to 48x27 I haven't had a successful print and my method of correcting the problems has failed me as I get unformed prints with lots of flashing.

Is my method completely off or should I continue to keep trial and erroring different exposures?

Here is a few pics of what I mean.

Out of curiosity does most of everyone print on 80x45 rather than 48x27?

I was printing really well on 80x45 by finding a system of correcting the exposure settings by a method of: If the item is unformed - raise the exposure... if it gets flashing - reduce it. This served me well and I was printing at about 90% success.

There is a 'brighter' side of the table which you can notice when projecting white after a print, which was the more successful side of the table, so I thought I would change to 48x27 to reduce this.

After changing to 48x27 I haven't had a successful print and my method of correcting the problems has failed me as I get unformed prints with lots of flashing.

Is my method completely off or should I continue to keep trial and erroring different exposures?

Here is a few pics of what I mean.